Mass production

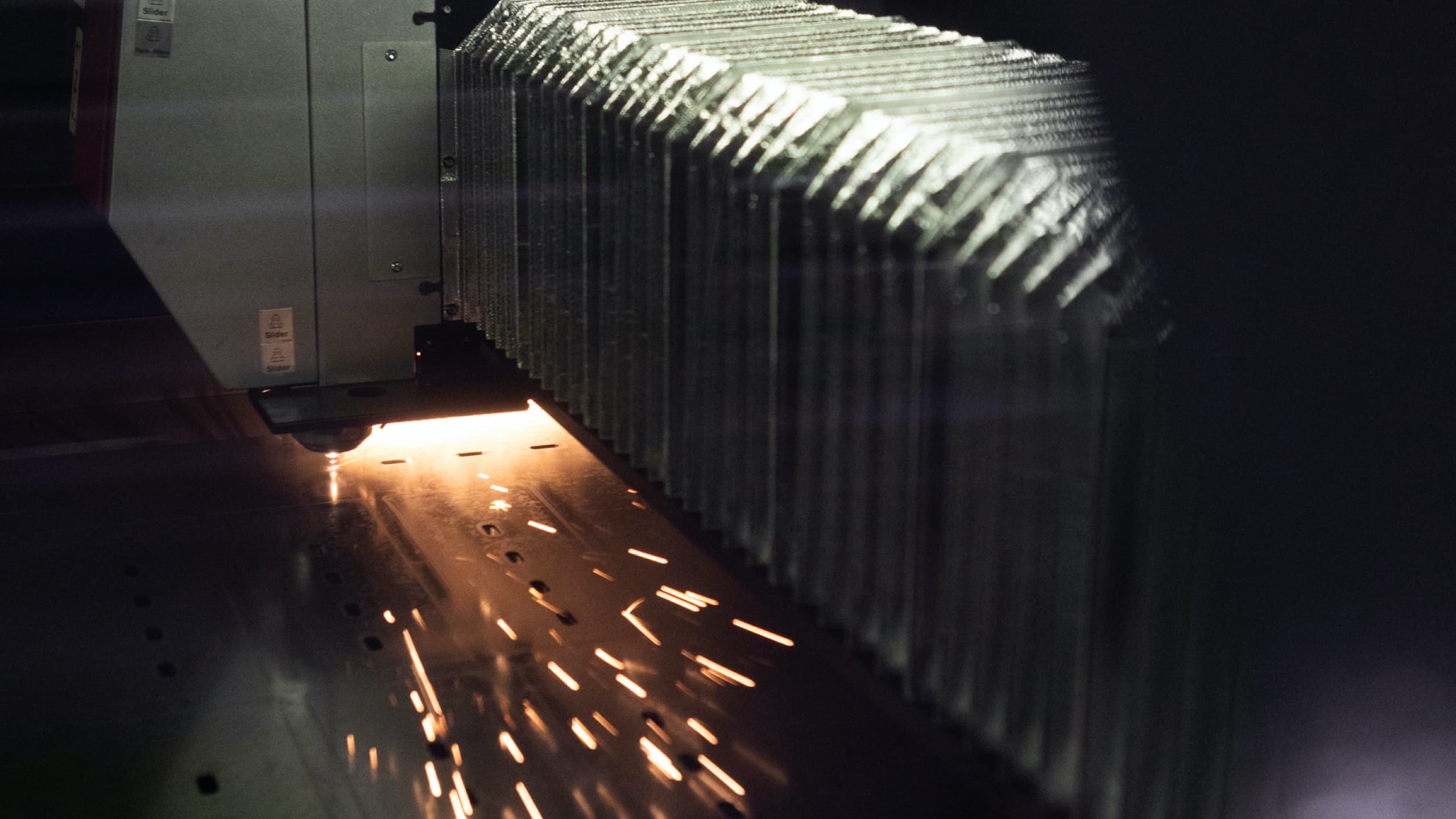

Customised mass production of metal for all production requirements.

Customised mass production of metal for all production requirements.

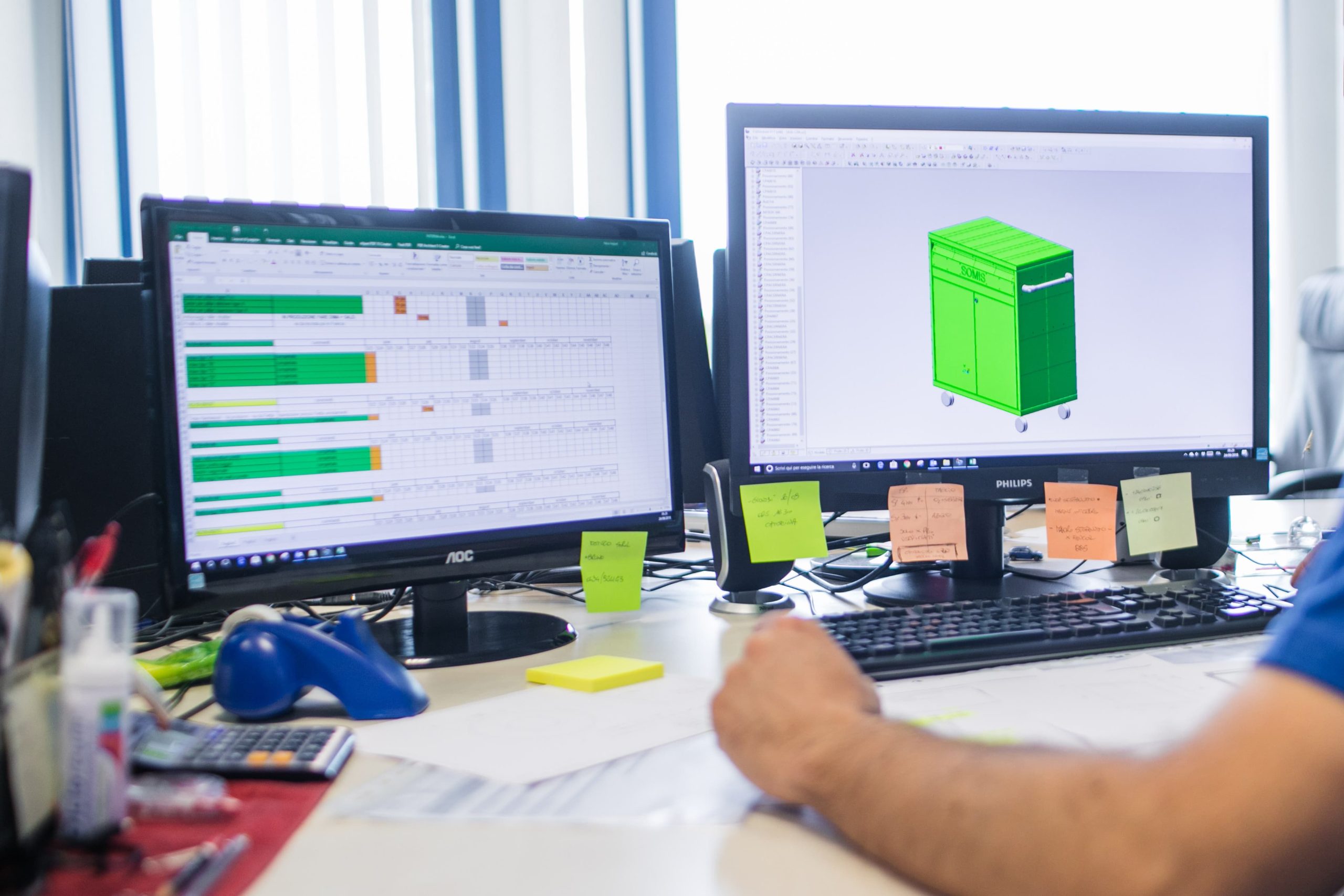

We design each single component of our products.

A turnkey service from the design phase to delivery.

Specialised in medium and light metal structural work.

We have gained long-standing experience in the sector.

These are not only aesthetic finishes but also processes that increase resistance and durability.

Technology, expertise and, above all, a wealth of experience.

Flexibility and versatility for every type of project